How are the segments/rim attached to the core?

Brazing uses a silver solder between the segment/rim and core and is heated until the solder melts and bonds the two together. Mechanical bonding uses a textured blade core to lock the segment/rim onto the edge of the blade. With laser welding a laser is used to weld the segment/rim and core together.

What type of edge?

A segmented edge offers a longer life and more durability than other types of blades. They are fast cutting and leave a relatively smooth cut (chipping may still occur). A continuous edge blade offers the smoothest cut. Serrated edge blades are also known as turbo blades given their faster cutting speed. Serrated edge blades provide a smoother cut and faster cutting rate combining the best qualities of both the other of blades.

What quality of blade are you looking for?

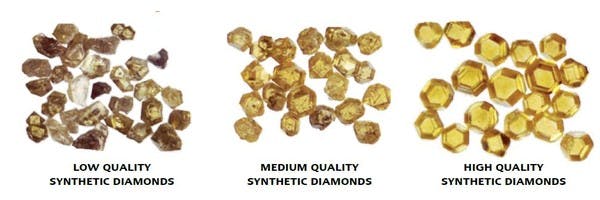

Diamond blades don’t actually cut, they grind and the exposed diamonds do the grinding work. Low quality bonds consists of weaker crystals with irregular shapes. These are used in lower priced diamond blades and because of the jagged points of the irregular shapes have a shorter life and lower cutting rates. Medium quality bonds consists of crystals that have a good strength and shape. These diamonds provide a longer life and better cutting rates. High quality bonds consists of crystals with the highest strength and an octahedral shape resulting in the longest life and fastest cutting rate.

What material are you cutting?

The number one rule to remember when choosing a diamond blade is to use a hard bond to cut softer materials and a soft bond to cut harder materials. With Diamond Products diamond blades a model number with a 7 has the softest bond and should be used to cut harder materials. 10 is the hardest bond and should be used to cut softer materials. 8 is considered a general purpose blade and will cut both hard and soft materials. Harder materials consist of reinforced concrete, general purpose concrete, and hard aggregate. Softer materials consist of asphalt, brick and block, and green concrete. A diamond blade that has a softer bond than necessary will always cut, but will not last as long as it should. A diamond blade that has a harder bond than necessary may not cut at all.