What's Happening

Our Products

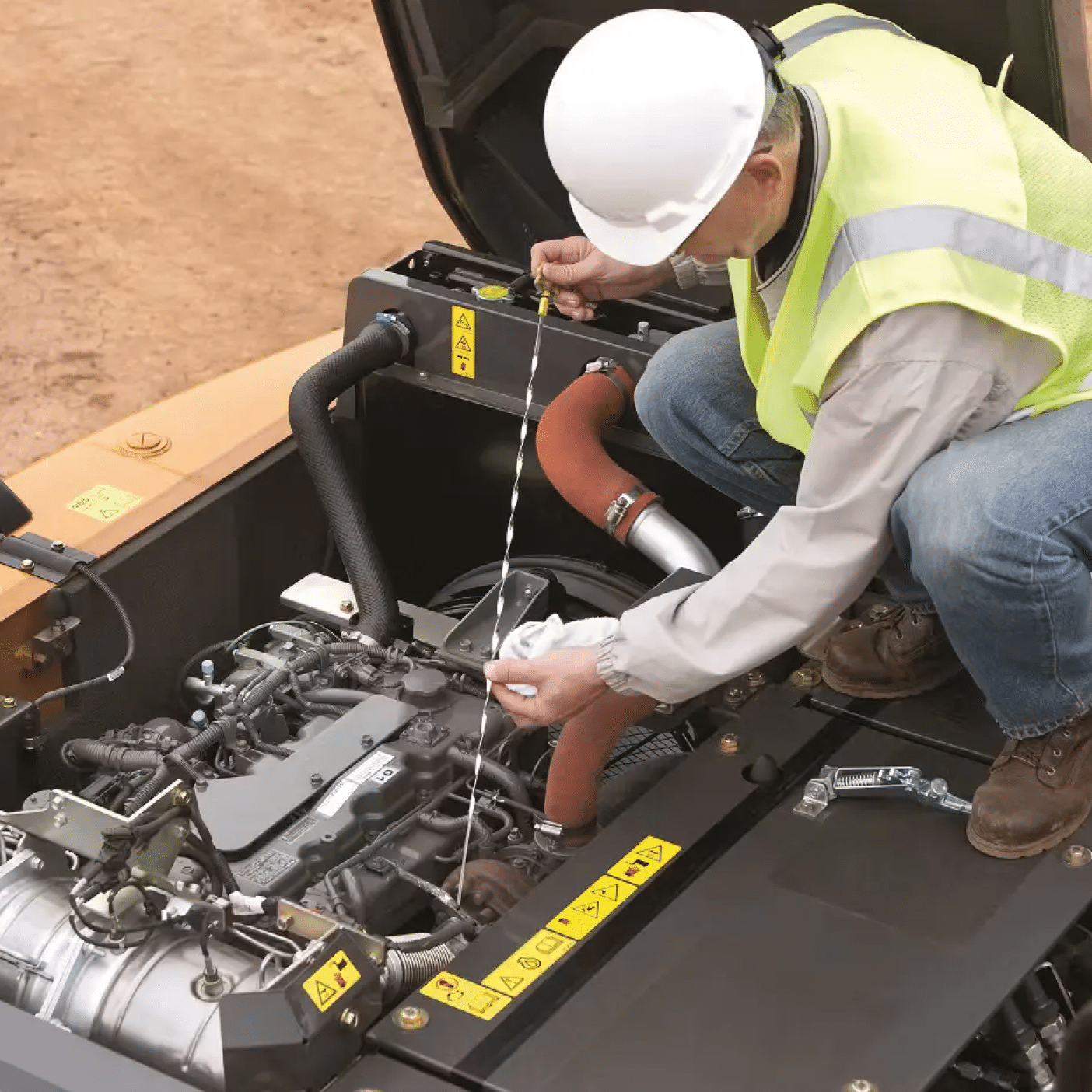

At Burris Equipment Company, we only offer the highest quality products and services to our customers. We offer a wide range of expertise that is sure to meet all of your equipment needs.

Construction Equipment

Landscape Equipment

Used Equipment

Rental Equipment

Service

Parts

Our Latest Articles:

Construction sustainability has become an important part of most building projects. Ensuring efficiency and protecting the environment are essential for making your business more appealing to potential customers and complying […]

The Most Important Tips for Heavy Equipment Washing Routine heavy equipment cleaning is vital for minimizing damage, enhancing operational efficiency, and extending the service life of your machines. However, like […]

Working in Sandy Soil: How to Do It Right Whether you’re excavating, hauling materials, or navigating through a site, operating in sandy soil can create issues with traction, trench stability, […]